BLEVE Incident Simulator for Windows

Simulation Software for LPG and Propane BLEVE Incidents.

Welcome to the BIS v1.0 WEBDEMO

In the next few pages we will walk you through a "partial" simulation using the BIS. You will see what the input process looks like and you will see some typical results. We will also point out some important features that make the BIS a good scenario analyzer and training tool.

please note: -- you are not actually running the BIS in this demo. You are just being shown what it looks like. The actual program is interactive -- you select the tank type, the fire type, etc.

final note: -- this page is under construction, you will find some of the graphics are poor, this is a problem with this webpage, not with the BIS. If you have a slow modem connection, please be patient it may take a few minutes to load.

Let us begin

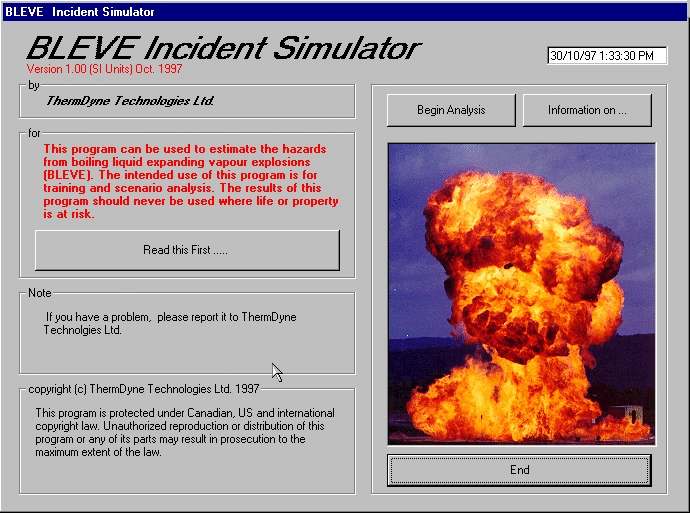

When you run the BIS the first page you see is as shown below. This is the title page of the BIS. As you can see, from this page you can do the following:

- read about the BIS

- do analysis of a scenario

- get some information about BLEVEs

- end the program

If you select "read this first", you will be told all about the BIS, including important facts like:

- how it is organized

- where it came from

- how accurate it is

- its limitations

- how well it is validated

- and more ...

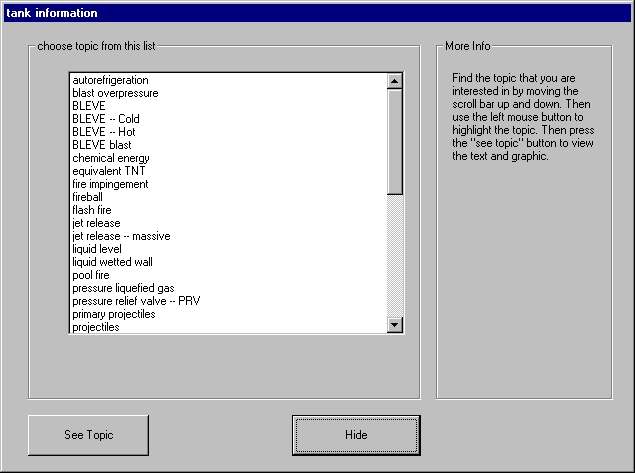

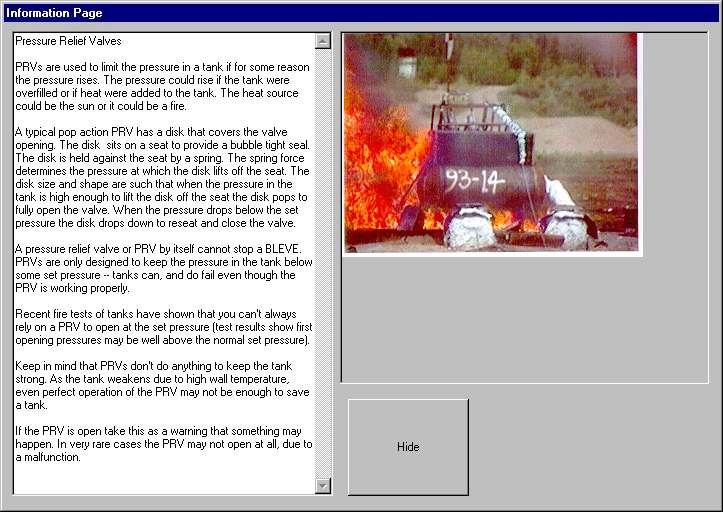

If you select the "more information" button, then the following page will appear. You will then be presented with a list of topics that you can select. Let us select the topic "PRV".

The PRV (or pressure relief valve) is an important safety device mounted on all LPG tanks. You need to know what it can do, and what it cannot do. There are myths out there about PRVs. You need to know the truth. These information pages contain basic information and tips that you should know.

There are many more pages of information including actual pictures of BLEVEs, fireballs, flashfires, ruptured tanks, jet fires, etc.

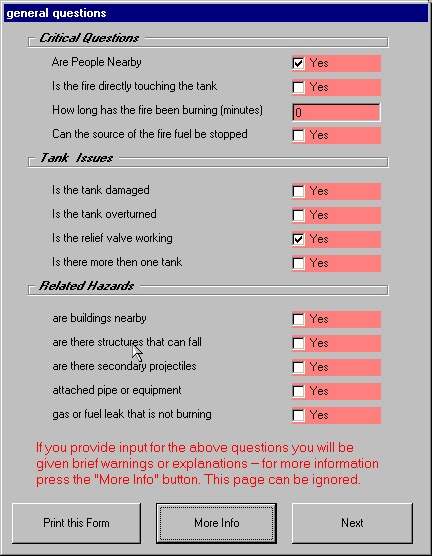

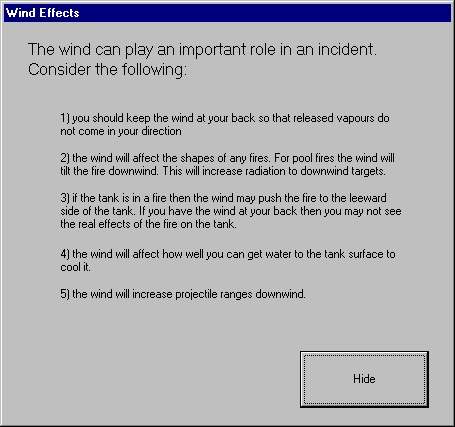

The next page that comes up has a series of questions about your scenario. You can ignore this page and carry on, or you can answer the questions. You will be given brief warnings and tips based on your responses. For example, if your scenario involves a windy day then the following tip will appear (see next page).

Wind can have many effects on a BLEVE Incident. The wind will affect the fire shape and this affects the tank weakening. The wind may push the fire to the leeward side of the tank. If responders approach from upwind they may not see the full effects of the fire. Wind will also affect any releases of gas.

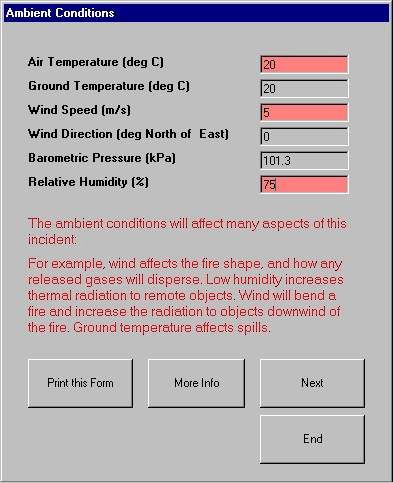

The next input page that comes up will ask you about the ambient conditions. Here you enter things like air and ground temperature and humidity. These can be very important, for example if it is a very cold day then the pressure in the tank may be much lower. If the tank fails while the lading is very cold then the blast and projectile hazard may be reduced. The opposite may be true if it is a hot day and the tank is in the sun.

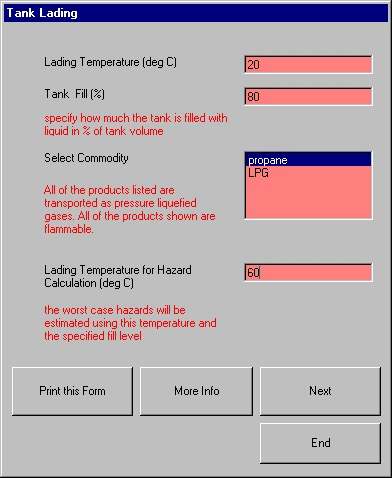

The next page asks you about the tank lading. For now the BIS only simulates LPG and propane. Here you answer questions about the tank fill. If you don't know the tank fill then usually it is safe to assume that it is 80% full. You can also specify the lading temperature for hazard analysis. This lets you study the effect of lading temperature on hazards.

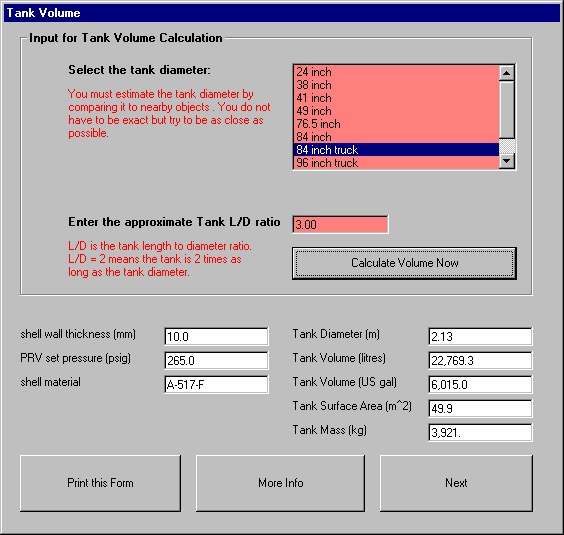

Now comes a very important part. You must specify a tank size. There are all kinds of tank sizes and it is very difficult to keep track of all the possibilities. The BIS makes it easy for you. If you don't know the tank size then you must "eyeball" the tank diameter and length. The BIS will then assign the most likely tank wall thickness, PRV setting, volume, surface area, etc. Now you are ready to estimate the hazards if this tank BLEVEs.

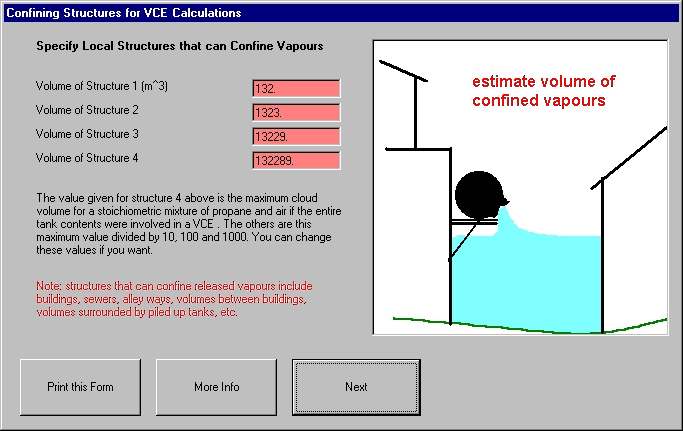

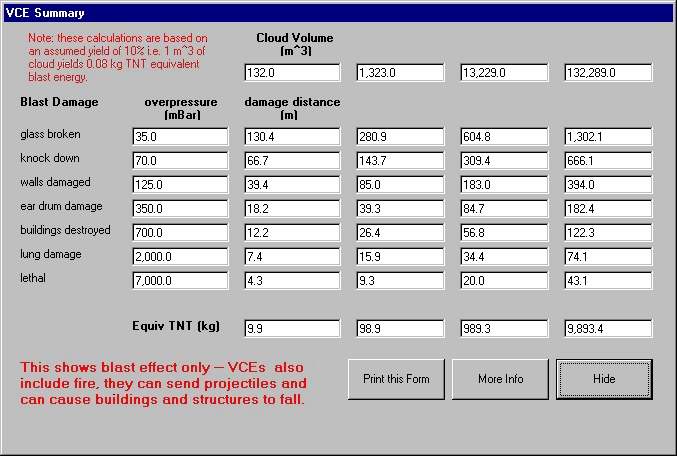

When you are at the site of a gas leak, or a potential LPG release you need to look around for places where gases can collect and be confined. If the gas is mixed with air and then it is ignited in a confined structure then a major explosion is possible. Here is your opportunity to estimate the vapour cloud explosion (VCE) hazard.

You need to estimate the volume of that old building or that culvert where gases can be trapped. If you don't know the volume then let the BIS show you the hazard from the default structure volumes. BIS will calculate the volume of the cloud if the entire tank contents are lost. Then it will select this volume, 1/10th, 1/100th and 1/1000th of this volume for hazard analysis. It is unlikley that the entire cloud will be involved in a VCE. It is more likely that 1/10th or 1/100th of the cloud is involved in a VCE. This will show you the range of possibilities. Remember you can always change these values if you want to study a specific case.

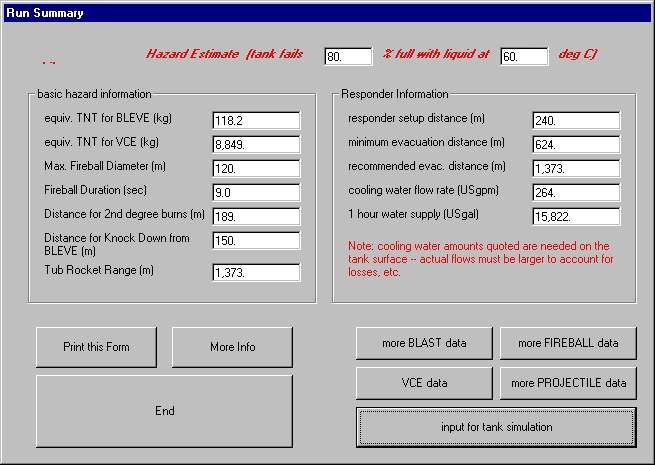

BLEVE Hazards Prediction

Based on your previous inputs, here are the hazard estimates. Blast, projectiles, fireball and VCE blast. It also gives you some important tactical information including:

- suggested responder setup distance

- minimum and recommended evacuation distances

- cooling water flow rates

- one hour water supply

As for the hazard summary, if you want more detail then you select the specific page. For example the next four pages show the fireball, blast, projectile and VCE blast hazards.

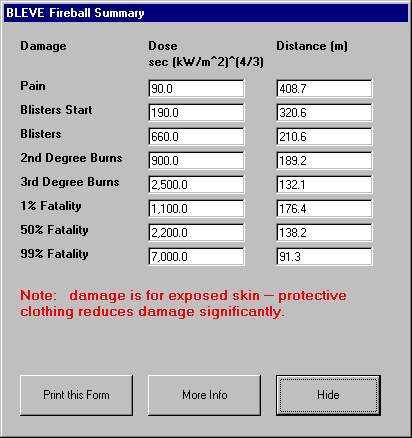

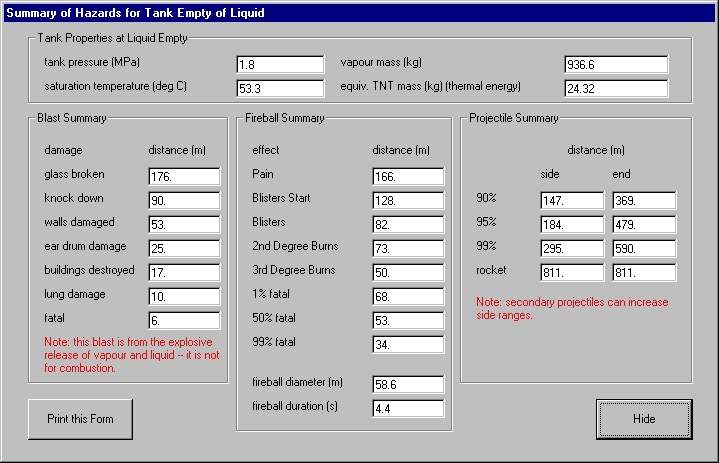

The fireball duration and size dictate the hazards due to thermal radiation. Here is a list of damage levels vs distance. As you can see the hazard drops quickly as the distance increases.

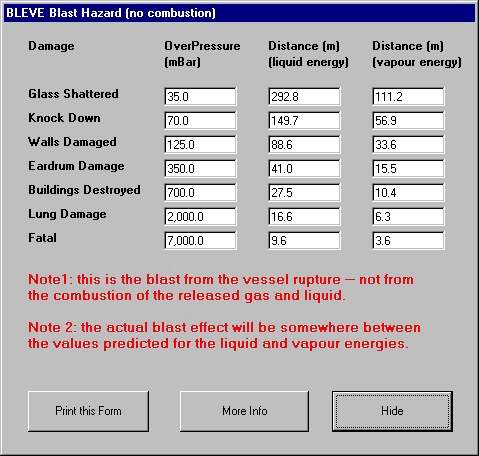

This blast hazard is from the explosive release of the compressed gas and boiling liquid. It is from the thermal energy stored in the lading. There is no combustion involved with this blast effect.

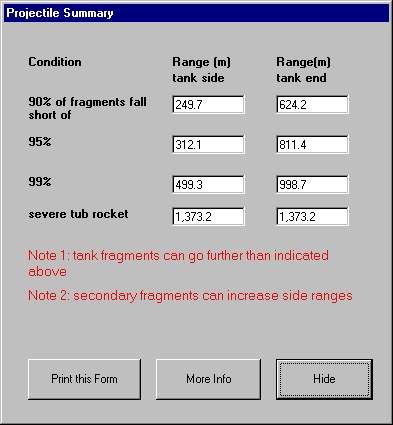

The stored thermal energy can propel the tank parts over large distances. In fact, the projectile hazard is the furthest reaching immediate hazard from a BLEVE. Note: you are not safe if you stand at the sides of the tank ! Look at the possible fragment ranges from the tank sides! Look at that tub-rocket range !!

The VCE blast is due to the rapid combustion of the confined gas releases. Here you are shown the blast vs distance for four different volumes of gas. This blast is due the chemical energy stored in the laeding. This is very different than the BLEVE blast!

Tank Thermal Model

Now that you have seen the hazard summary -- now it is time to simulate the tank in a given fire situation. From here you can see how the tank responds to different fire inputs. You can study things like how long it should take to empty the tank through the PRV, or how long before the tank is likely to fail.

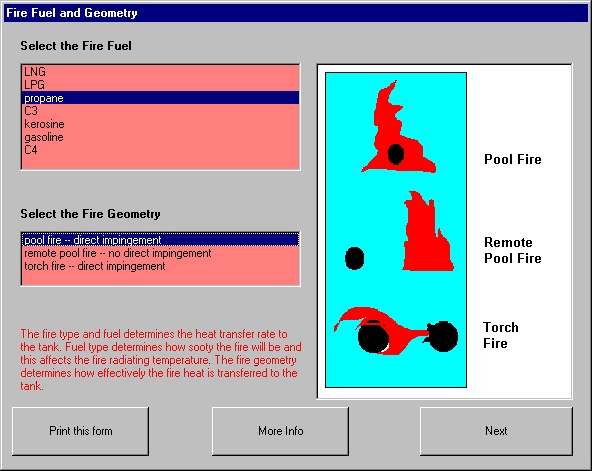

You can consider a wide range of fire types including:

- engulfing or partially engulfing pool fires

- remote pool fires

- torching fires

You select the fire type and fuel from the following page.

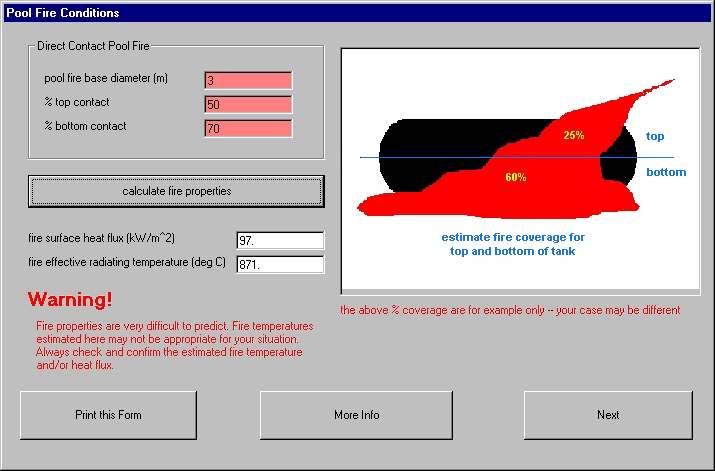

If you select the engulfing pool fire then this page will appear. Now you must give more details about the fire. How big is it? How much of the tank is engulfed in the fire?

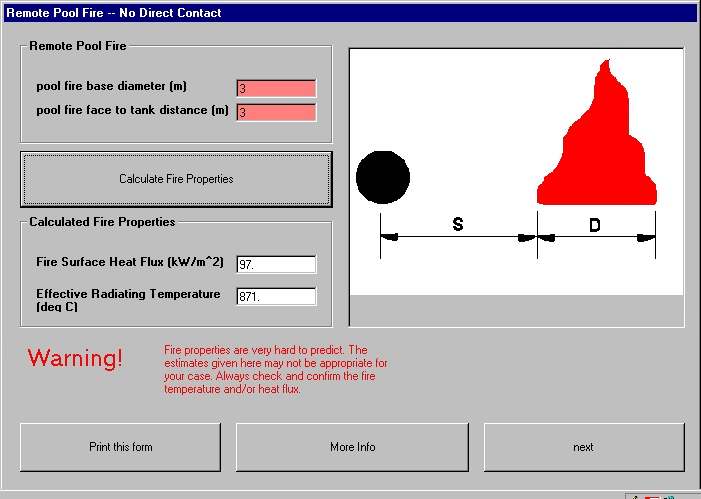

If you pick the remote pool case then the following page will appear. Here you must specify the pool fire size and the distance from the tank to the face of the fire.

If you select the torching fire case you must specify how much of the tank is being impinged by the torching fire. Torching fires can vary in severity so you also have the opportunity to play with the fire temperature.

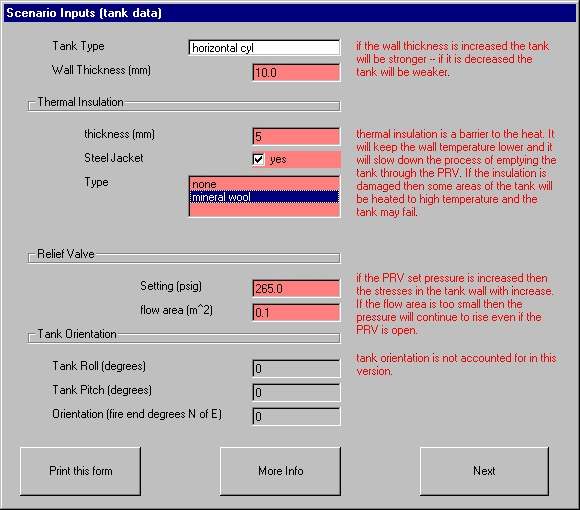

Now that you have selected the fire type, you can specify details about the tank you want to simulate. Here is your opportunity to learn about the effects of:

- thermal protection such as thermal insulation

- tank strength (i.e. wall thickiness)

- PRV size and set pressure

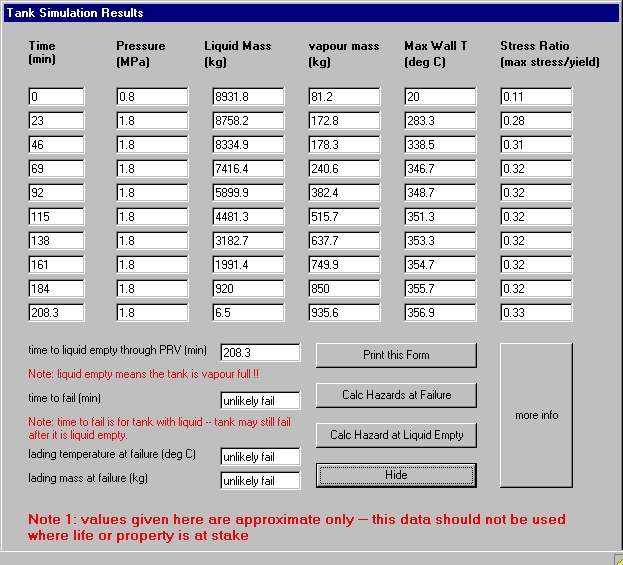

Tank Thermal Model Simulation Results

Here are the results of the thermal model simulation. Here you see how the tank changes with time. You are shown how each of the following change over time when the tank is in the fire:

- wall temperature

- liquid and vapour mass

- tank pressure

- tank stength and stress condition

Remember -- at any time you can click the "more info" button to learn more about any given aspect of the simulation.

How do the hazards change as the tank looses lading through the PRV? What are the hazards when the tank is empty of liquid? The BIS tells you this as well. The next page shows a hazard summary if the tank fails when it is empty of liquid. Even when it is empty it is a major hazard!!

From here you can choose to do more simulations, including:

- different fire types and exposure levels

- different tank diameters and lengths

- different lading temperatures, fill levels, etc.

- learn more about BLEVE Hazards,

- etc. etc.

We hope you have found this demo useful. We think you will agree that the BIS can give you answers to many of your questions about BLEVEs and their hazards.

If you still have more questions, please do not hesitate to contact us.

Windows XP is a Trademark of Microsoft Corporation. BLEVE Incident Simulator Copyright� 1997-2011, ThermDyne Technologies Ltd. All rights reserved. Made in Canada.